|

BAKING SODA BLASTING

CABINETS AND SYSTEMS

In 1991, Ruemelin

pioneered the high-performance dry blast cabinet for baking soda blasting.

Baking soda blasting addresses solvent substitution, waste minimization,

and pollution prevention goals as well as overall environmental objectives

in a wide range of industries. In addition, because it is completely

water soluble, baking soda helps eliminate passageway blockage that is

common with blast media such as glass beads and plastic abrasive.

The  surface

engineering properties of baking soda are another unique plus for many

applications, especially high-value component refurbishment. Under

proper operating conditions, baking soda can remove aerospace urethanes,

powder coat, e-coat, polymer coatings, adhesives, gasket material, greases,

oils, lubricants, and carbon residue. surface

engineering properties of baking soda are another unique plus for many

applications, especially high-value component refurbishment. Under

proper operating conditions, baking soda can remove aerospace urethanes,

powder coat, e-coat, polymer coatings, adhesives, gasket material, greases,

oils, lubricants, and carbon residue.

Baking soda blasting

cabinets and systems manufactured by Ruemelin Manufacturing Co., Inc. incorporate

patented purge ventilation technology. Purge ventilation is the feature

that distinguishes Ruemelin units from conventional abrasive blast cabinets

and that provides exceptional, uninterrupted visibility for blasting at

any pressure without regard for part configuration. This feature

is of vital importance when blasting with a highly friable single-use media

such as baking soda. Operator visibility is not only a productivity

and ergonomic factor, but also enables critical ongoing inspection during

the blasting process.

|

|

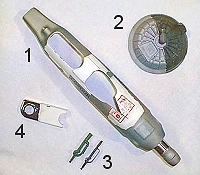

| 1. Aerospace

urethanes & decals |

|

| 2. CARC |

| 3. Polymer Coating |

| 4. Powder Coat |

|